GLS is the abbreviation for Glass-Fused-To-Steel Tanks.

Glass is fused with steel in order to enhance its strength. The explanation why glass is fused with steel is to enhance the properties of steel.

After fusing the steel with glass, the strength increases, the acceptable bracket of PH value for alkaline solutions widens, and the resistance of abrasion inflates.

Water Tank Indiaadopts European standards for enameling (glass lining) on steel. We import high tensile steel specially for enameling application. Enamel process on

steel is done at 850°C.One Coat One Fire. No-undercoat enamels with a complex bonding catalyst for PUESTA technology. The PUESTA powder electrostatic enameling technology makes it possible to obtain high-quality competitive products

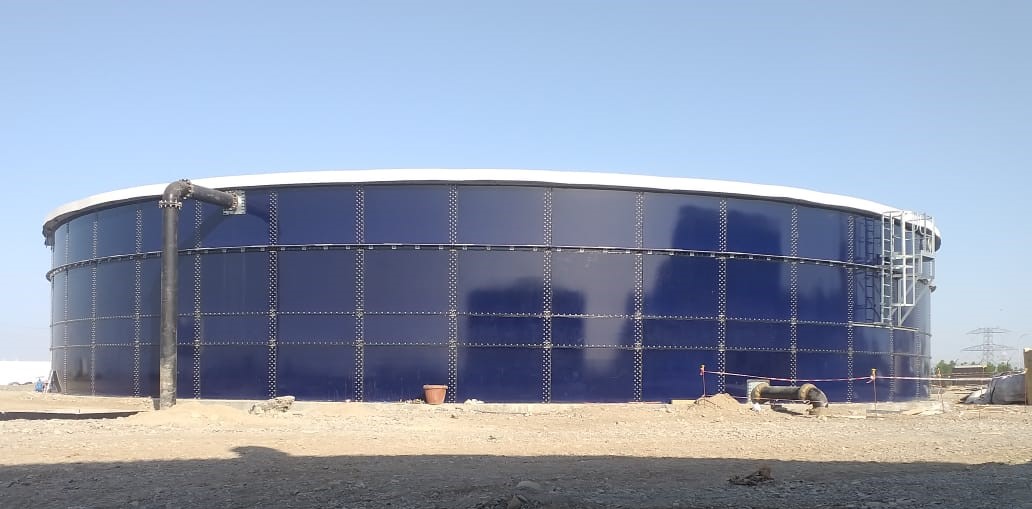

Glass Lined Steel Tanks

The enameling of steel is a thermical process which happens in the enameling-oven at about850° C. Thereby forming a glass layer on the outside of the steel,

this is a very tight bond, due to a chemical/physical process. The excellent protection of the glass lined steel against corrosion, the dielectric strength and

abrasion resistance, the hygienic surface, the temperature resistance and the resistance against aggressive media with excellent long-time resistance favor the use of enamel.

Quick and easy assembly, long lifetime and low maintenance make glass lined steel tanks very user-friendly. They are very strong and suitable for complicated applications like bio-reactors,

aeration- and clarifier tanks, sludge and biogas tanks, tanks for biological oil-products, silos and tanks for the storage of potable and wastewater and lots more. We don’t use nickel in

enameling process. All our production process is environment friendly safe for drinking water application as well Steel edges are curved and special edge protection method is adopted for high quality results.

DESIGN

1. Bolting system: An easy assembly and disassembly is guaranteed because of the checkered bolting system.

2. Center point plate: In the center of the panel connection there is a stainless steel center point plate. This guarantees the mechanical tightness of the system

3. GLS tank bolts: Our bolts do not have any holding edges which would damage the coating around the bolt holes. Stainless steel bolts are optionally available

4. Ultra Glass enamel coating: OurPUESTA Glass enamel coating provides high-resistant and elastic enamelwhich is free of nickel.

5. GLS Ring groove connection: We developed thering groove connection for the connection between foundation and tank wall. This leads to100% tightness and composite to the foundation

6. Enamel protection: Between every metal attachment and the enamel layer there is a synthetic interlayer which protects the coating againstdamage

7. Corner protection: The corners are protected by anadditional protective layer.

8. Rounded edges: As an option we round all edges.A total, all around corrosion protection is provided therewith.

9. Different panel sizes according to the project requirement. We achieve almost any desireddiameter and the panel weight is still easy toinstall.

10. Plate connection of top angle and bottomangle: By the special angle connections a solid and powerful ring with a smooth surface isgiven.

Advantages

The outstanding benefits of both materials are used for this

Glass protects from corrosion

Steel gives the strength and flexibility

Impact and abrasion resistant

Hygienic surface

Climate and weather resistance

No bacteria on the surface

Temperature resistant

Above 35 years design life

Maintenance free

Applications

Water Tank India – Glass Lined Steel Tanks are widely used for:

Water and Waste Water Storage

Raw water storage

Fire Water storage

Irrigation Water storage / Rain water harvesting

Effluent and Sewage Water storage

Oil and Diesel Storage

DM Water Storage

Molasses Storage

Biogas Storage Tank

Drinking water storage